Steel

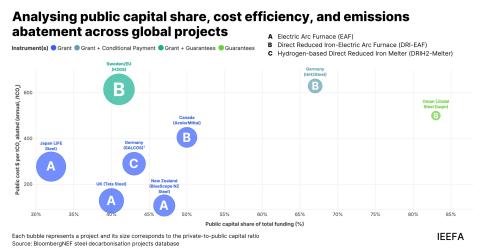

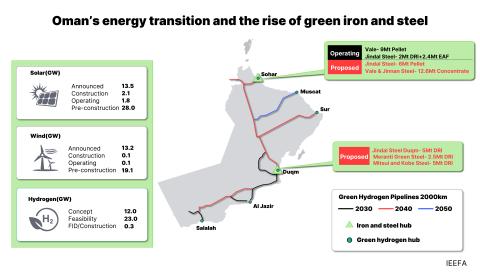

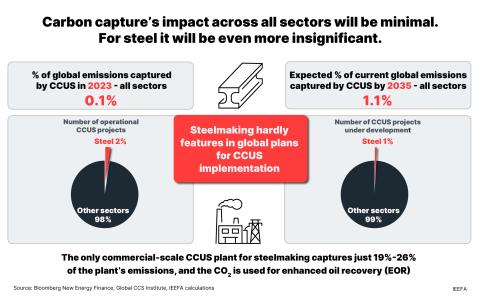

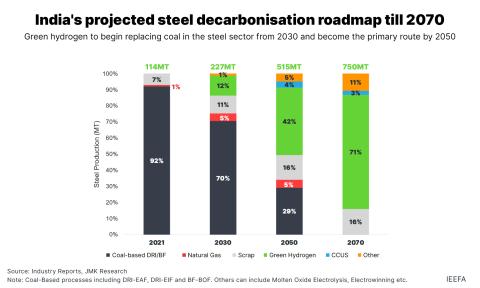

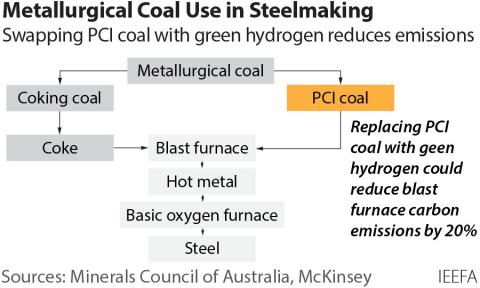

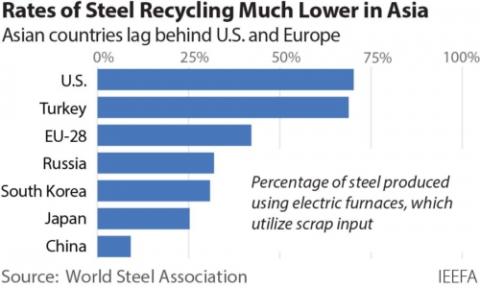

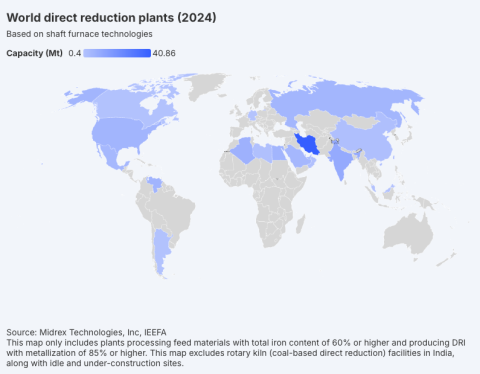

Global steelmaking is dominated by coal-consuming blast furnaces. However, blast furnaces are now increasingly challenged by alternative technology that does not use coal — namely direct reduced iron (DRI) furnaces and electric arc furnaces (EAF). These technologies are not new; they are already used at commercial scale globally. DRI technology runs on gas rather than coal but is ready to use increasing amounts of green hydrogen as an alternative. Almost all steelmakers around the world that have announced commercial-scale, low-carbon iron and steelmaking capacity have opted for DRI and EAF, not carbon capture and storage (CCS) retrofits for blast furnaces.

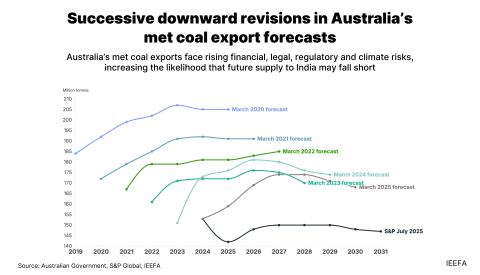

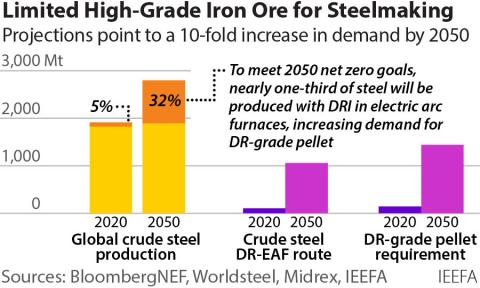

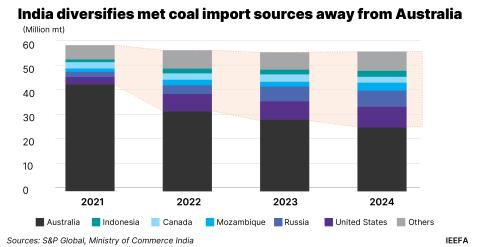

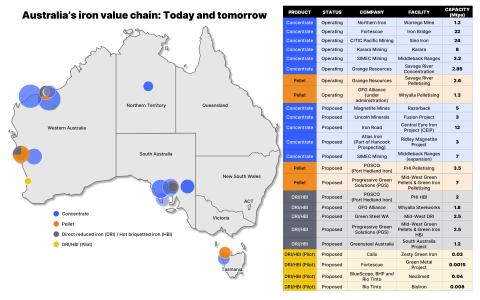

The steel sector’s switch to DRI and EAF has clear implications for the future of metallurgical coal. It also has implications for iron ore mining, as DRI currently requires higher-grade ore than that used in blast furnaces. IEEFA’s research and analysis tracks the fast-moving technology shift underway in the iron and steel sector and the implications for iron ore and metallurgical coal.