An iron and steel to-do list for BHP’s next CEO

Key Findings

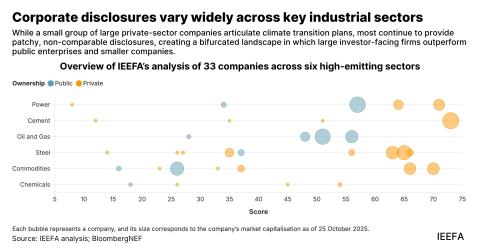

BHP lags its peers when it comes to the steel technology transition. Its next CEO must scale up capital allocation to address the transition and decarbonisation.

There is a significant risk BHP is underestimating the pace of the technology transition, and overestimating the resilience of metallurgical (met) coal demand.

BHP’s backing of carbon capture and storage (CCS) must end. It has a poor track record, an unimpressive outlook and will not prop up long-term met coal demand.

BHP should cease further coalmine expansions and, as global met coal demand falls, responsibly manage down capacity as it has done with its Mt Arthur thermal coalmine.

This analysis is for information and educational purposes only and is not intended to be read as investment advice. Please click here to read our full disclaimer.

BHP’s next CEO has a list of things to do if they want the company to stop looking like a steel technology laggard among its peers.

Following Rio Tinto’s naming of its next CEO, it is widely expected BHP will soon begin searching for its next CEO to replace Mike Henry. Several possible internal candidates have been highlighted.

As Rio and BHP focus more on energy transition metals such as copper, they face significant changes in the iron ore market as China’s steel demand continues its structural decline and steelmakers seek to address their high emissions intensity.

While demand for lower, blast-furnace grade iron ore will be affected by falling Chinese demand, producers of high-grade iron ore suitable for lower-carbon steelmaking expect a demand boost as steelmakers seek to reduce emissions.

The processing of iron ore into iron and steel dominates the iron ore majors’ Scope 3 (indirect) emissions. BHP’s Scope 3 emissions amounted to 377 million tonnes (Mt) in FY2024. Neither BHP nor Rio Tinto have a Scope 3 carbon emissions reduction target.

Rio is at least targeting increased production of higher-grade iron ore that can lower steelmaking emissions. It already produces high-grade ore in Canada, and will shortly add to that from its huge Simandou project in Guinea.

Rio Tinto has also called for the reintroduction of carbon pricing in a recent submission to Australia’s Productivity Commission.

In contrast, BHP is sticking firmly with Pilbara iron ore suitable for blast furnaces, and remains Australia’s biggest exporter of the metallurgical coal they consume.

BHP Australia president Geraldine Slattery – a contender to be the next CEO – stated in a social media post in July that, “It’s clear the biggest reduction in carbon emissions from steelmaking over the next two decades will not come from reinventing iron ore processing in Australia, but rather from advances in China’s blast furnaces – which we expect to run for at least 20-30 years.”

It can therefore be expected that BHP will continue to be a big supporter of carbon capture and storage (CCS) as a way to reduce blast furnace emissions, despite the technology’s poor track record of failure and its highly dubious outlook for the steel sector.

In the latest setback for CCS in the steel sector, ArcelorMittal is considering shutting down its “flagship” carbon capture project in Belgium after only two years of operation. The project captures less than 2% of the steel plant’s emissions.

Instead of CCS, steelmakers serious about reducing emissions are turning to direct-reduced iron (DRI) technology, which doesn’t use coal. The global pipeline of new DRI projects amounts to production of about 100Mtpa, while the announced commercial-scale CCS projects for coal-based steelmaking languish at 1Mt, according to Agora Industry.

BHP has announced CCS projects with steelmakers such as ArcelorMittal, HBIS and JSW Steel, with little to show for them, while its trials using Pilbara iron ore in DRI processes with China Baowu appear to have made progress.

Given the size of Pilbara exports, finding ways to use this lower-grade ore in DRI-based processes is essential to reduce steel emissions. BHP has joined the NeoSmelt consortium that is working on such technology.

However, as has been highlighted by the Australasian Centre for Corporate Responsibility, BHP’s disclosed capital allocation for steel decarbonisation – just US$75 million over the FY2025-29 period – is not even close to the scale of its Scope 3 emissions problem.

BHP risks overestimating the long-term resilience of metallurgical coal demand

There is a significant risk BHP is overestimating the long-term resilience of metallurgical coal demand. Continued failure of CCS will only add to those doubts.

While Rio Tinto exited coal in 2018, BHP wants to extend its Peak Downs met coal mine well into the next century.

The Australian government recently downgraded its medium-term metallurgical coal exports forecast yet again, while S&P Global forecasts that growing imports by India will not be enough to offset declining imports by Japan, Korea and particularly China (see figure below).

S&P Global forecasts a slow decline in Australian exports to 2035 but the risk looks to be on the downside as India seeks to increase domestic met coal production, and diversifies imports away from Australia.

Additionally, BHP’s met coal comes with a previously under-appreciated methane emissions problem that is attracting more attention and calls for action.

To do list

To address these issues and resolve BHP’s laggard status, the next CEO should do the following:

- Manage down its existing met coal capacity responsibly rather than extend or divest it. BHP’s approach on the closure and transformation of its Mt Arthur thermal coalmine has set a precedent.

- End support for CCS, a decades-old technology that has continuously demonstrated it is unable to reduce emissions sufficiently, and is clearly being utilised by corporations and governments globally to justify business-as-usual.

- Increase capital allocation for steel decarbonisation towards technologies that can reduce steelmaking emissions significantly, particularly DRI. BHP could increase investment in technologies that can use Pilbara iron ore in DRI-based steelmaking and/or develop high-grade iron ore as its peers are doing.

In addition, the new CEO may assess another approach to acquire Anglo American, if it hasn’t happened already. A takeover would again focus on Anglo’s copper assets but its high-grade iron ore mines ought to be of more interest to BHP if a second approach is made.