Labour shortages, not royalties, are driving up costs at Australia’s underground coalmines

Key Findings

Sustained high operating costs and labour shortages are putting pressure on margins for coalminers across NSW and Queensland, not government royalty rate increases.

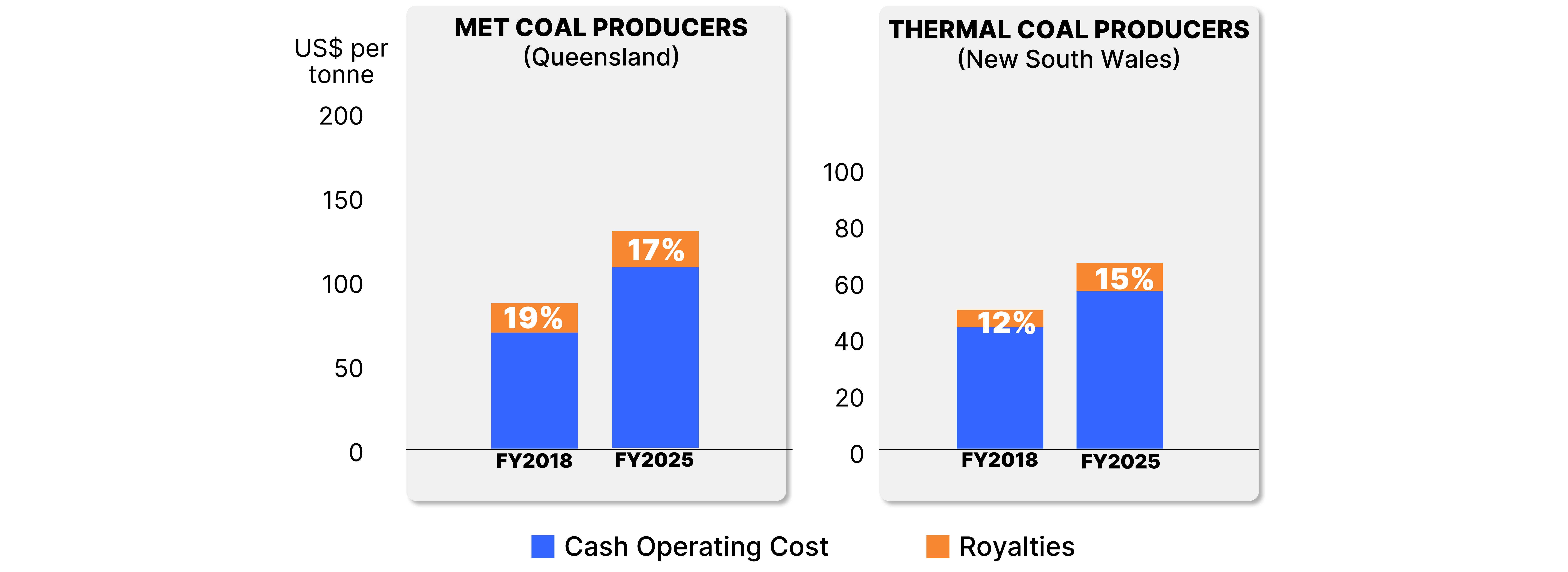

In 2025, royalties were a smaller proportion of total unit operating costs for Queensland coalminers than in 2018, while in NSW there was a slight increase in the same period.

Coalmines face further operational challenges due to a severe skills shortage in critical mine safety roles – exacerbated by new regulations and training requirements.

This analysis is for information and educational purposes only and is not intended to be read as investment advice. Please click here to read our full disclaimer.

Persistently high operating and financing costs are impacting many coalminers across NSW and Queensland, putting pressure on margins, with profits of a number of miners plunging into the red.

Coal prices surged during the energy crisis of 2022-23 but have since declined. For FY2025, they approximate pre-COVID levels last seen in FY2018. Miners’ cash costs have increased during this time and remain elevated. There are a range of contributing factors, which IEEFA examined in a recent article, particularly rising labour costs. However, the impact of recent increases to royalty rates should not be overstated.

Miners’ costs and royalty impacts

Queensland mainly produces metallurgical (met) coal, for which prices have eased during 2025. According to the International Energy Agency’s mid-year coal review, “Although adverse weather conditions and logistical disruptions in Queensland constrained Australian export volumes, demand from Asian steelmakers remained insufficient to provide sustained upward pressure on Australian Premium Hard Coking Coal prices. As a result, prices remained below USD 200 per tonne, a level that has placed increasing pressure on the profitability of several coking coal producers.”

Bowen Coking Coal entered voluntary administration last week, blaming, in part, Queensland’s royalty rates, which increased in 2022. However, the windfalls during the 2022-23 energy crisis have declined, and the state’s coal royalty take is expected to halve in FY2024-25.

Benchmark premium hard coking coal (HCC) averaged US$193.33 per tonne in FY2025, slightly below the FY2018 price of US$203.11, according to S&P data. Yet over this period, median unit cash costs, excluding royalties, for Queensland’s met coal producers have risen by about 50%.

Queensland’s royalty increases mainly affected Tier 1 HCC producers because the new tiers are triggered only at elevated price points. Nevertheless, royalties are a now lower proportion of the state’s major met coalminers’ unit costs, comprising 16.6% of total cash costs, down about three percentage points from 2018.

NSW produces mainly thermal coal. Benchmark thermal coal has averaged US$122.09/t in 2025, compared with US$100.50 for 2018, according to S&P data. Over this period, unit costs for the main thermal coal producers, excluding royalties, have risen by about 30%. The NSW government increased royalty rates by 2.6 percentage points for all types of coal from 1 July 2024. Royalties now account for about 15% of total cash costs for the major NSW thermal coal producers, up about three percentage points from 2018.

Figure 1: Mines' rising cash operating costs far exceeding royalties

Source: Company reports.

Note: Queensland Met Coal cash costs – median of major met coal producers: Peabody Seaborne Met Coal, Anglo Steelmaking Coal (based on guidance excl. impact of mine closures), BMA (guidance midpoint) and Stanmore Resources (guidance midpoint). Royalties are calculated per Queensland royalty regime before and after changes introduced in July 2022, and considering producer product mix relativities to benchmark HCC prices.

NSW Thermal Coal: cash costs – median of thermal coal producers: Peabody Seaborne Thermal, Yancoal (guidance mid-point), Whitehaven (FY2024) and Glencore Energy Coal. Royalties are calculated per NSW royalty regimes before and after change, and assuming average price realisation of 85% NEWC price.

The changing cost structure for underground mines

Some recent improvements in unit costs are being reported, generally via increased coal production rates. In open-cut mines, strip ratios have fallen in FY2025 (according to NSW statistics) as they seek to maximise profits in the short term. Underground mines have also increased coal production rates. Some miners are investigating autonomous methods, such as Anglo American, which has established remote operations centres (ROC) for its underground coalmines. While the main benefit is removing workers from hazardous underground work environments, managing mining remotely may also offer some labour productivity upside. CSIRO has estimated automation in longwall mining could improve labour productivity by 5-10%. BHP has launched an AI hub in a bid to improve safety and lift productivity.

Amid these sustained high costs, new pressures are emerging. Environmental regulations such as Australia’s Safeguard Mechanism have a significant influence on costs at underground mines as companies must either invest in environmentally sustainable practices to minimise their methane emissions or purchase and surrender carbon credits. Further, new regulations proposed by the NSW Environmental Protection Authority will impose additional requirements on underground mines for methane emissions monitoring and abatement.

Labour costs have a pronounced impact on unit costs in underground mines, especially if production levels are affected. Underground mining costs are mainly fixed – the costs of operating and maintaining equipment and a safe working environment don’t change with production levels. That translates into higher unit operating costs whenever production falls or outages are experienced.

Meanwhile, the Fair Work Commission has enforced equal pay rates between direct hire and labour hire employees performing the same job. As a result, BHP was ordered to pay an average annual increase of $30,000 to some 2,200 coalminers. Industrial disputes over the issue at the Metropolitan and Ulan underground mines have affected production and raised costs. This will be a permanent added cost.

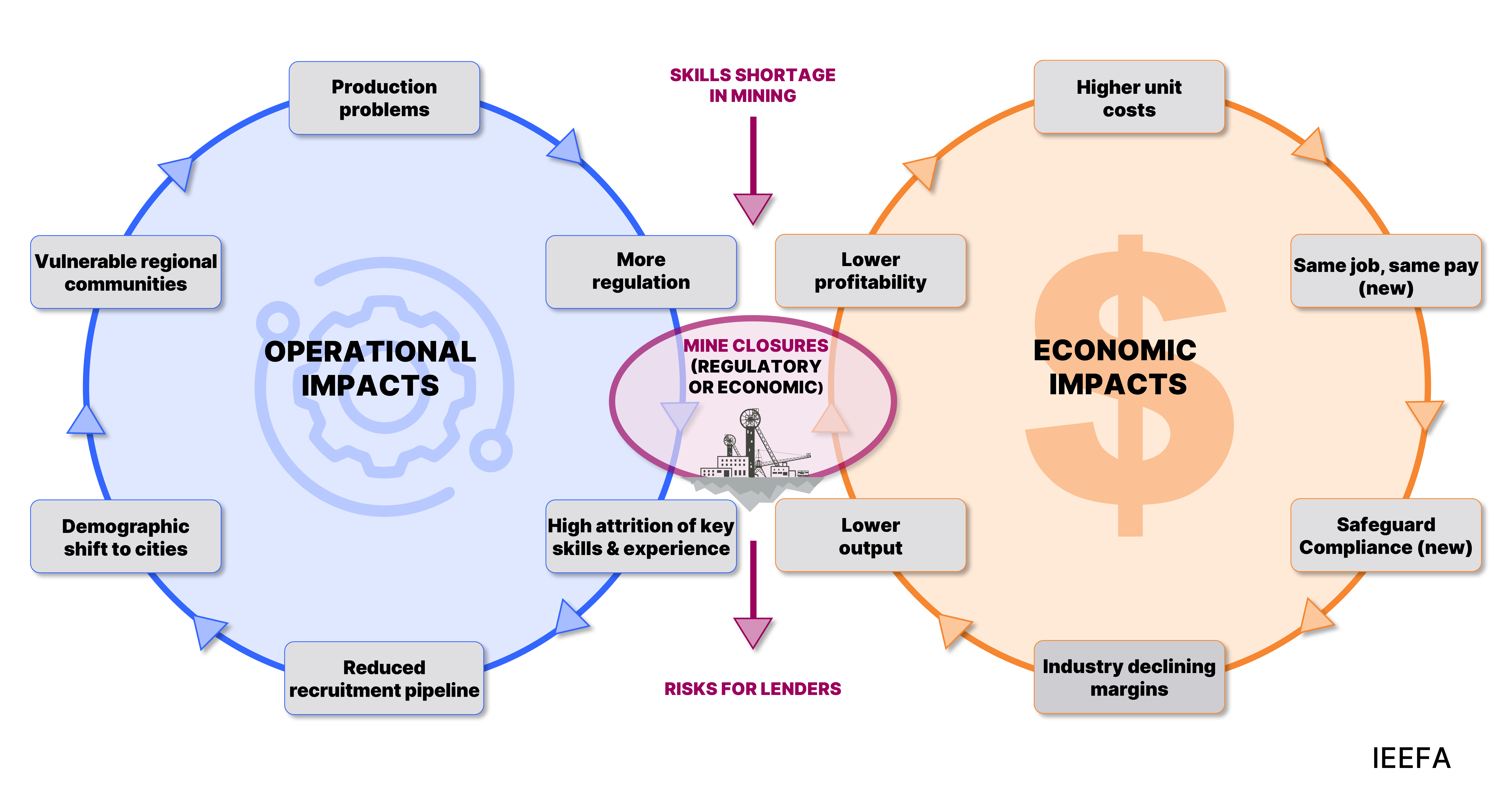

Labour shortages are no longer a cyclical workforce issue, but rather a persistent structural challenge that could reshape mining investment returns and industry sustainability, with various reinforcing loops.

Labour demographics – a ticking time bomb

All major Australian coalmining companies conduct some underground mining. According to the Australian Bureau of Statistics, coalmining employed a record 45,900 employees and contractors in June 2024. About 30% (14,000) work in the 30 underground mines operating across NSW (17) and Queensland (13), with an average of about 500 workers per mine.

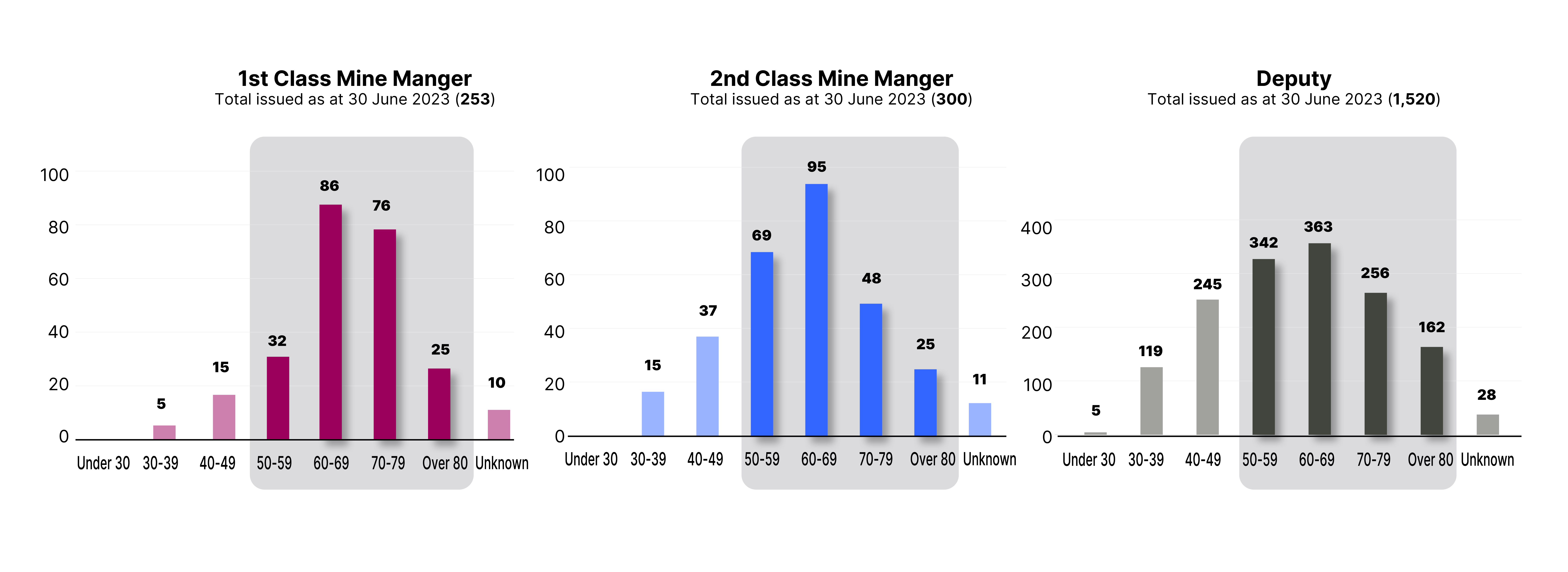

The workforce is ageing, with the average age for statutory mine operation roles falling in the 60-69 group (Figure 2), which means an entire tranche of key players are approaching retirement.

Figure 2: Aging coalmining workforce in key statutory roles

Source: Annual Report of the Board of Examiners. Note: Graph based on the latest available data; age demographics for 2023-24 have not been reported.

Of more concern is the talent pipeline for crucial leadership and safety management roles. There is a 10-year lead time to develop qualified workers, but universities are cutting mining engineering and geoscience/earth sciences programs.

Almost every university in eastern Australia has cut undergraduate courses in earth sciences, including ANU, Macquarie and the University of Newcastle (Geology). They also produce fewer than half of the mining engineering graduates required for the future. In late 2024, the University of Wollongong retained its mining engineering program only following significant industry and community pressure.

In 2023, 152 mining engineers graduated in Australia, less than half the reported peak of 333 in 2015. The decline in graduates reflects a slump in enrolments. In 2024, Mining Digital reported that enrolments in mining engineering across Australia had fallen by 63% since 2014, stating, “Mining is no longer seen as an aspirational career choice.” Low enrolments in turn reduce the viability of universities continuing to offer these courses.

New regulatory pressures for key safety roles

In the stalled Anglo coal sale process, Peabody commented that with two mines closed and losses building, there are “questions around both the availability and willingness of the workforce to resume safe underground longwall mining ... if regulators ever allow it”. Mine outages due to methane incidents highlight the ongoing issues – and attract ever increasing attention from the safety regulator and the public. Shortages of qualified people could pose not just operational challenges but potential regulatory compliance issues that could lead to operations being halted if critical controls are absent or ineffective.

Figure 3: Mining’s skills shortage – a vicious cycle caused by systemic factors

Mining faces a persistent safety skills shortage due to workforce demographics, industry consolidation and mine closures, an ageing workforce and tighter requirements for qualifications and training.

For the pipeline of new recruits, there are extended periods of training for new statutory positions while universities are dropping pathway courses as they become unviable.

This vicious cycle of critical labour shortages and rising costs impacts mines’ financial sustainability. The loss of experienced staff through retirement, retrenchment or mine closures outstrips the pipeline of new or retrained workers. The demographic, educational, regulatory and economic factors create a self-perpetuating crisis that could threaten the industry’s ongoing viability.

The coalmining sector faces interconnected challenges, as demonstrated by recent financial results. These developments affect various stakeholders, including financial institutions, contractors and government, while raising questions about environmental compliance costs and site remediation obligations. For financial services with coal exposure, labour market constraints represent a strategic consideration beyond traditional operational metrics.