BHP is lagging its peers on Scope 3 and steel technology transition

Download Briefing Note

View Press Release

Key Findings

BHP risks underestimating the speed with which the steel technology transition will eventuate. Technology shifts have a habit of happening faster than expected.

The company continues to place high emphasis on carbon capture despite the growing likelihood that this technology will not play a major role in decarbonising coal-based steelmaking.

There is a significant risk that BHP is overestimating the long-term resilience of metallurgical coal demand.

In contrast to its peers, BHP is not targeting production of high-grade iron ore suitable for low-carbon steelmaking, a grade seeing growing demand.

This analysis is for information and educational purposes only and is not intended to be read as investment advice. Please click here to read our full disclaimer.

BHP’s new Climate Transition Action Plan (CTAP) does nothing to alter perceptions that it is lagging behind its peers when it comes to credible steel technology change and Scope 3 carbon emissions, according to the Institute of Energy Economic and Financial Analysis (IEEFA).

BHP continues to place high emphasis on carbon capture, utilisation and storage (CCUS) to reduce its Scope 3 emissions despite the growing likelihood that the technology offers limited potential for decarbonising coal-based steelmaking.

BHP is planning to stick to the production of lower-grade iron ore suitable for coal-based steelmaking in blast furnaces, and metallurgical coal. The company is the only one of the ‘Big Four’ iron ore majors still mining coal. Therefore it is in its BHP’s interests to promote the idea that steel decarbonisation (and hence Scope 3 reductions) will come from retro-fitting blast furnaces with CCUS, allowing it to continue to supply met coal and its blast furnace-grade iron ore – in other words, business-as-usual.

Scope 3 emissions are released when BHP’s customers process the raw materials it supplies. BHP’s Scope 3 emissions make up 98% of the company’s total emissions (Scopes 1, 2 and 3), and result mostly from the processing of the iron ore and metallurgical coal it supplies to steelmakers. The company does not have a measurable Scope 3 emissions reduction target.

While BHP continues to focus on stalled CCUS technology, its peers are shifting emphasis to production of more high-grade iron ore suitable for low-carbon steelmaking in direct reduced iron (DRI)-based steelmaking processes. Vale, Rio Tinto, Fortescue and Anglo American already produce iron ore of sufficiently high quality for DRI-based steelmaking (DR-grade). They are all planning increased production in response to growing demand for DR-grade ore as steelmakers switch to technology that can realistically reduce emissions.

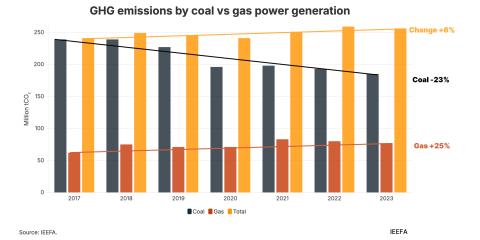

To date, virtually all plans for commercial-scale, low-emissions primary steel plants are DRI-based, not coal and carbon capture-based. According to German think tank Agora Industry, the 2030 project pipeline includes 96 million tonnes per annum (Mtpa) of DRI capacity and just 1Mtpa of CCUS for blast furnace-based steelmaking. CCUS for coal-based steelmaking is already being left behind by alternative technology, as has happened in other sectors like power generation.

BHP risks underestimating the speed with which the steel technology transition will eventuate. It maintains in its new its CTAP that there are no near zero emissions technologies for iron ore-based steelmaking that are ready for widespread commercial adoption. One of the key assumptions behind its new 1.5°C scenario is that hydrogen-based DRI technology will not be available until the mid-2030s.

However, Stegra – the new name for H2 Green Steel – will begin production of truly green iron and steel using green hydrogen-based DRI at commercial scale from 2026. Stegra is already planning further green iron and steel plants in Brazil, Portugal and Canada.

Technology transitions have a habit of happening faster than expected. As a result, there is a significant risk that BHP is overestimating the resilience of long-term metallurgical coal demand.

In its new CTAP, BHP makes clear that it doesn’t see any threat to metallurgical coal demand on the horizon. BHP plans to extend the life of its Peak Downs metallurgical coal mine out to 2116, 66 years beyond Australia’s target to reach net zero emissions.

However, with CCUS highly unlikely to ever enable low-carbon coal-based steelmaking, and the steel technology transition away from blast furnaces accelerating, there is a significant risk that long-term metallurgical coal demand will fall faster than expected.

The Australian Government’s Department of Industry, Science and Resources (DISR) forecasts in its most recent medium-term outlook that Australian metallurgical coal exports will peak in 2026 before falling through the rest of the decade. Moreover, DISR has a history of being over-optimistic with its forecasts of Australian metallurgical coal exports.

BHP looks to be continuing a largely business-as-usual plan for its iron ore and met coal production in the belief that CCUS will prop up long-term demand for both. BHP’s strategic approach to steel technology change has diverged from other major iron ore exporters. It is looking like a technology and emissions laggard.