PCI coal for steelmaking the first metallurgical coal grade to be impacted by decarbonisation

Download Full Report

Key Findings

Use of green hydrogen considered a promising way to decarbonise steel

An early use of green hydrogen in the steel industry will be in existing blast furnaces to replace pulverised coal injection (PCI) coal

To reduce emissions, steelmakers are slowly starting to shift from blast furnaces to low-and zero-emissions steelmaking processes that don’t use coal

PCI coal is facing an increasingly challenged future with Rio Tinto, BHP, BlueScope and Thyssenkrupp highlighting and exploring alternative options to its use

PCI coal will be the first grade of metallurgical coal impacted by the decarbonisation of steel

Executive Summary

Much of the long-term opportunity for green hydrogen in steelmaking is via its use in direct reduced iron (DRI) processes. However, the replacement of pulverised coal injection (PCI) coal with hydrogen in blast furnaces looks like being an early decarbonising application.

The replacement of pulverised coal injection (PCI) coal with hydrogen in blast furnaces looks like being an early decarbonising application.

Lower-cost PCI coal is injected into blast furnaces to reduce coking coal consumption. Essentially high-quality thermal coal, PCI coal can be sold into either the metallurgical or thermal coal markets.

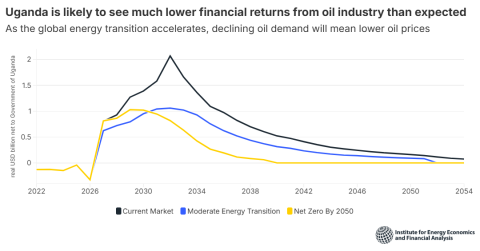

Wood Mackenzie sees PCI coal coming under particularly high pressure under a 2˚C scenario with demand falling 50%. However, Wood Mackenzie’s scenario depends on a high roll-out of as yet unproven carbon capture and storage (CCS) technology. In the event that such a CCS uptake does not occur, emissions reductions via other methods would need to be increased to remain in line with 2˚C and PCI coal consumption would need to drop even further.

German conglomerate Thyssenkrupp began the first industrial-scale test of PCI coal replacement with hydrogen in November 2019. The replacement of PCI coal with hydrogen remains a key, early emissions reduction pathway for the company.

Australian steelmaker BlueScope’s initial measures to reduce carbon emissions are focused on blast furnace improvements. The company is planning to replace blast furnace PCI coal consumption with coke oven gas, which contains 60% hydrogen. Following this, coke oven gas will be complemented with green hydrogen to reduce PCI coal use further – the company has plans to work with the Commonwealth Scientific and Industrial Research Organisation (CSIRO) and Shell on pilot hydrogen production projects for this purpose.

BHP has highlighted lower grades of metallurgical coal, such as PCI coal, have a challenged future. The company has noted that the first widespread use for hydrogen in steelmaking is likely to be in the replacement of PCI coal in blast furnaces. Holding on to its hard coking coal assets, BHP has started divesting mines that produce lower-quality metallurgical coal including PCI coal.

BHP announced an agreement to sell its 80% holding in the BHP Mitsui Coal joint venture – which produces PCI coal along with lower-quality coking coal – to Stanmore in November 2021.

Further, BHP appears to be planning to sell at least one of its mine holdings within its BHP Mitsubishi Alliance (BMA) joint venture. The most likely to be sold are the Blackwater mine, producing lower-quality coking as well as thermal coal, and the Daunia mine, producing lower-quality coking coal and PCI coal.

As with BHP, Rio’s first priority when it comes to reducing its Scope 3 emissions is blast furnace optimisation. Rio Tinto has highlighted that reducing carbon emissions from blast furnaces will involve the use of higher-grade iron ore and the replacement of PCI coal with hydrogen, echoing the view that PCI coal is facing an increasingly challenged future as steelmakers and iron ore suppliers come under mounting pressure to reduce emissions.

Russia supplies Europe with almost all of its low-sulphur PCI coal. The EU ban on Russian coal imports – to take effect from August 2022 – will clearly have a major impact on this trade.

Australia is the only other major supplier of PCI coal but is unlikely to be able to make up for lost Russian supplies. This is reflected in Australian PCI coal prices which S&P recorded as high as US$645/tonne in March 2022.

At this stage of the global energy transition, high coal prices – as well as energy security concerns – are only likely to accelerate a transition towards alternative technology, including the replacement of PCI coal with hydrogen. In an April 2022 research note, Moody’s highlighted that an extended period of high coal prices would accelerate the long-term decline in coal demand, as alternative technology looks even more favourable.