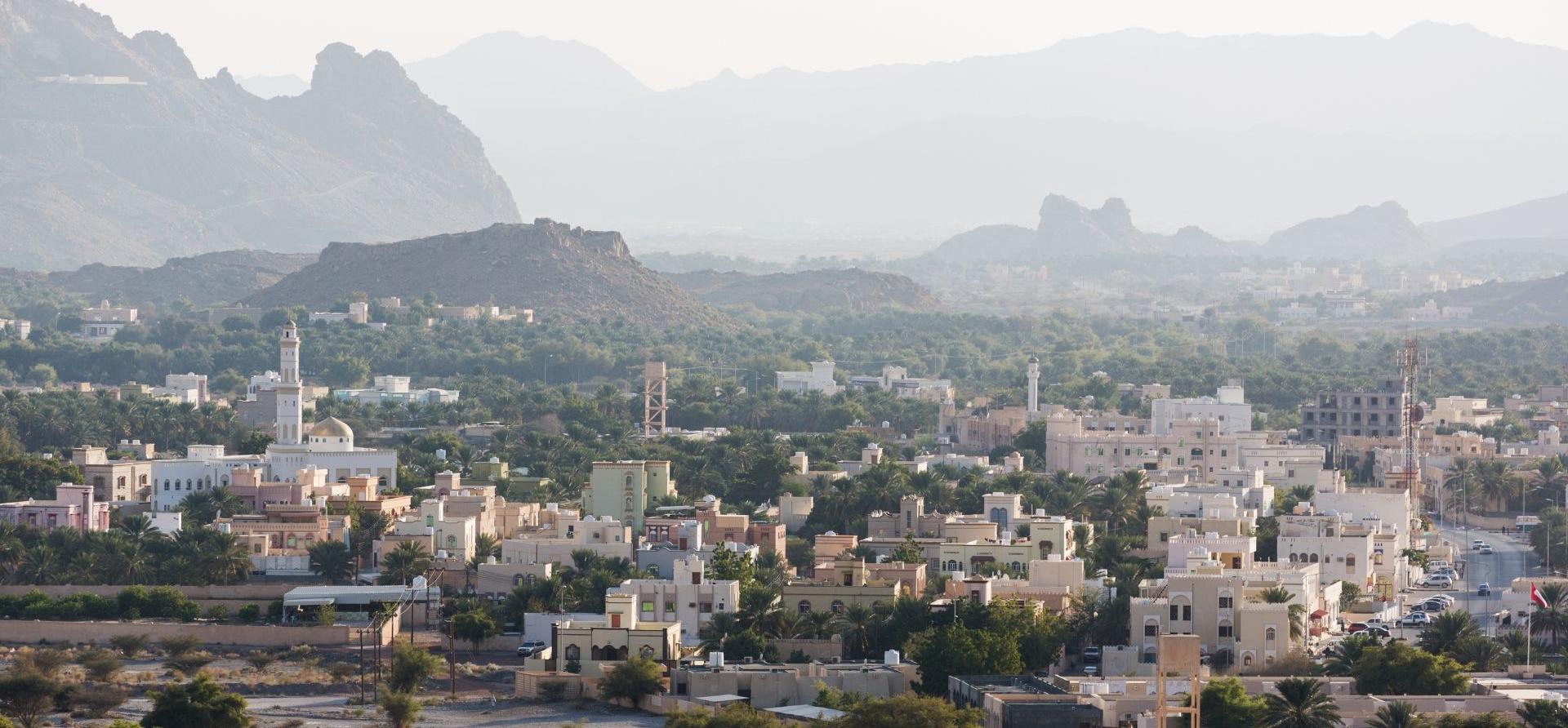

Oman forges ahead as a green iron and steel hub

Key Findings

Oman is adopting flexible ironmaking technologies, incorporating hydrogen from the outset as the new standard for low-emissions iron and steel.

Other developers could follow Oman’s hybrid approach, gradually transitioning from gas to 100% green hydrogen as a practical pathway to producing truly green iron and steel.

The Omani government shows that a successful transition requires not only access to renewable energy sources and strategic location, but also a robust, supportive and structured regulatory framework that helps derisk the shift for investors.

Oman’s steel sector

Oman is one of the few nations in the Middle East and North Africa (MENA) region with an integrated steelmaking supply chain, from global iron ore concentrate supply to electric arc furnaces (EAFs) for steelmaking. While the country has no domestic iron ore production, this established industrial base provides a solid foundation for transitioning towards low-emissions and ultimately green iron and steel.

Vale and Jindal Steel remain the key players in Oman’s steel sector; however, new international entrants such as Meranti Green Steel, Mitsui and Kobe Steel, and Jinnan Steel are reshaping the market and positioning Oman prominently in the global transition.

Based on announced projects, Oman is expected to establish its first concentration plant, with a capacity of 12.6 million tonnes a year (Mtpa), by mid-2027. Furthermore, 12.5Mtpa of new direct reduced iron (DRI)/hot-briquetted iron (HBI) capacity has been announced in Duqm – Oman’s emerging ironmaking hub. This includes 5Mtpa under construction at Jindal Steel Duqm. The other two proposed initiatives – Meranti Green Steel and Mitsui and Kobe Steel – have not yet reached final investment decision (FID). By establishing these new capacities, Oman aims to position itself as a regional hub for iron production.

All newly announced DRI facilities are based on flexible shaft furnace technologies (Energiron or Midrex Flex), allowing producers to use up to 100% hydrogen for iron ore reduction from the start. While Jindal Steel plans to incorporate hydrogen into the mix at a later stage, Meranti Green Steel, which is expected to reach FID by 2026 intends to use 15% green hydrogen from day one.

Jindal Steel’s 6Mtpa pelletising facility was scheduled for commissioning in the final months of 2025, with the potential to supply the planned DRI plants in Duqm.

Iron and steel value chain plants in Oman

Renewables and hydrogen potential

All new iron and steel initiatives are underpinned by Oman’s natural endowments, including its significant potential for renewable energy and green hydrogen production. The country has also set a net-zero target for 2050.

Oman’s Vision 2040 has a target to reduce oil’s share of GDP to less than 10%, signalling its ambition to move away from reliance on fossil fuel exports. The country has set clear targets to expand its renewable energy portfolio, with significant investments in solar and wind power. Oman has over 12.2 gigawatts (GW) of announced solar power capacity, 25.3GW in pre-construction stage, 2GW under construction and 1.7GW operational. For wind power, announced projects total about 13.2GW, 19.1GW in pre-construction, with only 100MW under construction and 50 megawatts (MW) operating.

Backed by its strong renewable energy potential, Oman has also set ambitious targets for green hydrogen production, with more than 35GW of announced projects at the concept or feasibility stage. However, only a few have reached FID.

A gas-rich country with ambitious plans for green hydrogen

The three large-scale DRI projects in Duqm, with a combined capacity of 12.5Mtpa, will require about 3.33 billion normal cubic metres (about 130 petajoules) of gas, equivalent to nearly a quarter of the country’s gas exports. Although Oman has sufficient cheap gas to start gas-DRI production, the government remains firmly committed to the transition. Oman has a clear plan to reduce its reliance on gas, and the evidence suggests the new DRI facilities will not remain gas-based for long. The shift to green hydrogen is already well under way.

Gas-based DRI is emissions-intensive, and it is not possible to produce green iron and steel with gas. Without transitioning from gas to green hydrogen, these projects – like other gas-based DRI plants – will not attract a green premium in the market, as their emissions would still exceed the threshold for near-zero iron classification (even those equipped with carbon capture).

Midrex, which accounts for nearly 80% of global DRI production via shaft furnaces, has stated clearly that carbon capture and storage (CCS) is unlikely to play a significant role in reducing emissions from DR technologies.

The Integrated Gas Company has signed contracts allocating 18.614 million standard cubic metres per day of gas for industrial consumers in Duqm – the highest allocation among all regions and industrial hubs in Oman. However, Dr Ali bin Masoud Al Sunaidy, chairman of the Public Authority for Special Economic Zones and Free Zones (OPAZ), noted: “So yes, we are allowing a transition period for industries until power from green energy becomes more competitive – which it already is … The green steel project is already under construction and designed to transition to green energy in due course.”

Hydrogen for steel

Oman aims to produce 1-1.5Mtpa of green hydrogen by 2030. To achieve this target, it has established a clear and co-ordinated strategy to derisk investment, led by Hydrom, the national hydrogen master planner. The strategy focuses on the development of shared infrastructure, bridging supply and demand gaps, offering financial incentives, and streamlining regulatory processes.

Of the announced initiatives, only a few have indicated plans to allocate their hydrogen production to steelmaking, including the Amnah project and, more recently, India’s ACME Group, a renewables and hydrogen developer that is building a green ammonia plant in Oman.

ACME Group has signed a binding agreement with Vietnamese steelmaker Stavian to supply 0.8Mtpa of green hydrogen-reduced DRI/HBI for 10 years. To support this agreement, ACME is considering establishing its first DRI facility, with a planned capacity of 1.2Mtpa, likely to be in Duqm.

Meranti Green Steel has secured non-binding offtakers for its 2.5Mtpa of HBI, with additional interest from potential offtakers for the project’s second phase of equal capacity. The company has also secured multiple offtake agreements for steel production from its Rayong plant in Thailand. CEO Sebastian Langendorf said: “Green HBI is no longer just an idea. It is becoming a bankable, merchant input for green steelmaking.”

To manage this long-term transition, steelmakers must act as long-term offtakers for green hydrogen to help get the sector off the ground.

The way ahead

Starting with a mix of hydrogen and gas demonstrates commitment from iron and steel producers, but having a clear pathway to gradually increase the share of hydrogen is equally important. Each producer should clearly outline how it plans to raise the proportion of hydrogen in its reducing mix over time.

Studies indicate that while Oman can produce gas-based DRI at low cost with limited competition from other regions, it also has the potential to supply H2-DRI to key markets such as Europe cost-competitively, holding an advantage over other producers, including Australia.

Oman’s approach is setting a new benchmark for producers considering green iron production and the broader transition ahead. With flexible technologies already available and ambitious future targets in place, shifting from gas to green hydrogen could become the standard for all DRI facilities – not only in the MENA region but globally.

This article was first published in the Jan/Feb issue of Steel Times International.