Small-to-medium scale industries emerging as key growth drivers for India’s natural gas consumption

Efforts should increase to adopt cleaner and more efficient alternatives to reduce reliance on natural gas, which carries the risks of price volatility, limited domestic production, import dependence, and expensive infrastructure. Efforts should increase to adopt cleaner and more efficient alternatives to reduce reliance on natural gas, which carries the risks of price volatility, limited domestic production, import dependence, and expensive infrastructure.

Key Takeaways:

The increased availability and affordability of domestic natural gas have led to a surge in its use by small-to-medium scale industries, such as tea plantations, manufacturing, liquefied petroleum gas (LPG) shrinkage and sponge iron.

The limited availability of domestic natural gas raises questions about the viability of using domestic gas in the long term by small- to medium-scale industries.

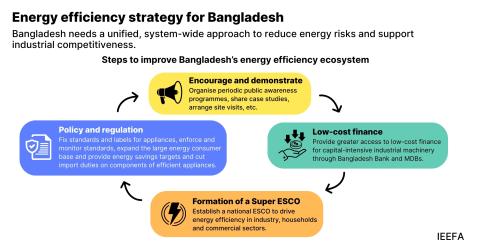

There are various clean and efficient solutions available, such as increasing energy efficiency and enhancing the use of renewable energy to cut the increasing dependence on natural gas.

India’s small-to-medium scale industries should focus efforts on cleaner options like enhancing energy efficiency and greater use of renewable energy for reducing their reliance on natural gas, which carries several long-term business risks, according to a new briefing note by the Institute for Energy Economics and Financial Analysis (IEEFA).

The note finds that small-to-medium scale industries, such as tea plantations, manufacturing, liquefied petroleum gas (LPG) shrinkage and sponge iron, now are the second largest consumers of natural gas in India, behind only the fertiliser sector. Gas consumption by such industries has grown 136% to 16,639 million metric standard cubic metres (MMSCM) in the fiscal year (FY) 2023-24 from 7,060MMSCM in FY2019-20.

“Small-to-medium scale industries have taken advantage of low domestic natural gas and liquefied natural gas prices to use them in their production processes. However, such fuels carry the risks of price volatility, import dependence, limited domestic production and expensive infrastructure,” says Purva Jain, Energy Specialist, Gas & International Advocacy, IEEFA.

“Solutions are available to minimise this increasing dependence on gas, which can hamper the commercial viability of small-to-medium scale industries when gas prices rise. It is essential to focus on energy efficiency and enhance the use of renewable energy in these industries,” she added.

The note finds that the surge in natural gas use by small-to-medium scale industries came on the back of significantly higher domestic gas use. One of the key reasons for this is the increased availability of domestic gas, complemented by lower prices for domestic gas from April 2023. Domestic gas use by the industrial sector has been on the rise and has gone up from 3,651MMSCM in FY2019-20 to 13,169MMSCM in FY2023-24. Connectivity to city gas distribution grids and lowered domestic gas consumption by the fertiliser sector could be some of the reasons for the increased availability.

“In April 2023, the government had linked domestic gas prices with the Indian crude basket and capped it at US$6.5/Metric Million British thermal units (MMBtu) (Rs4,699/MMBtu) for legacy fields for two years. This has helped limit the increase in domestic gas prices, improving its affordability. With this, the viability of domestic gas as an input fuel for small-to-medium scale industries, which operate on limited profit margins, has increased,” says Jain.

However, given the volatility in global gas prices and the proposed deregulation of domestic gas prices in 2027, the note suggests using alternatives such as electricity, green hydrogen and biogas and focusing on energy efficiency to limit gas use.

For tea plantations, using tea waste and garden waste can also help produce compressed biogas, which has the same methane content and calorific value as natural gas and is a cleaner alternative.

Further, the note recommends hydrogen blending in industries that depend on piped natural gas (PNG). It highlights that India’s leading power producer, NTPC, has already successfully achieved hydrogen blending in PNG pipelines in the townships of Surat and Solapur. Green hydrogen can also be a key clean alternative for the sponge iron sector as a reductant for producing direct reduced iron (DRI).

Similarly, the note suggests using electric heating powered by renewable energy rather than natural gas-based heating for the glass manufacturing sector. Tea plantations and ceramic production can also use such an alternative.

“A cluster-based approach can work for industries such as ceramics, tea, glass and sponge iron,” says Jain. All the above solutions will be more efficient and profitable in clusters due to demand linkages.

“Improving energy efficiency can play a critical role in lowering carbon emissions in industries like ceramics and glass. Many small or unorganised industries that use natural gas for heating suffer massive heat loss and release of pollutants due to inefficient combustion,” she adds.

Read the briefing note: Domestic Gas Drives Industrial Consumption in India

Media contacts: Prionka Jha ([email protected]); Ph: +91 9818884854

Author contacts: Purva Jain ([email protected])

About IEEFA: The Institute for Energy Economics and Financial Analysis (IEEFA) examines issues related to energy markets, trends, and policies. The Institute’s mission is to accelerate the transition to a diverse, sustainable and profitable energy economy. (ieefa.org)