Louisiana petrochemical project is a losing bet for investors and local communities

Download Full Report

View Press Release

Key Findings

If Mitsubishi and the state of Louisiana go forward with a proposed 350,000-ton methyl methacrylate production facility in Ascension Parish, La., the company will likely face negative financial consequences and the government will waste taxpayer dollars.

Slower economic growth, weak project financing, disruptive trade realignments, market challenges, sustainability options and growing public opposition create a risk profile that challenges the Geismar project.

Mitsubishi’s stakeholder outreach fails to pass muster in the context of corporate sustainability and human rights concerns.

Multi-layered human rights, environmental and climate issues now tear at the reputational credibility and creditworthiness of large global companies—including Mitsubishi.

Executive Summary

Mitsubishi is making a bet on a proposed new 350,000-ton methyl methacrylate (MMA) production facility at the Geismar site in Ascension Parish, La. It’s a big bet—the largest MMA facility in the world.

It’s a bad bet. The company seems to know it as it has missed two construction start deadlines and is currently beyond the most recent promise to start construction by the end of the second quarter of 2024.

Louisiana’s leadership welcomed the announcement in 2020. Little attention was paid to the potential risks. If Mitsubishi goes forward with the project, the company will likely face negative financial consequences. An investment of approximately $1 billion (¥143 billion) is equivalent to 47% of the Mitsubishi Chemical Group’s 2023 capital expenditure budget.1,2 This amount and the company’s reputation are at risk. Louisianians, on the other hand, will have lost good land, the right to plan their own communities, clean air, land and water, and taxpayer dollars. What Louisianians give up is, for the most part, irretrievable.

When the project was announced, a final investment decision (FID) was expected in mid-2022 with construction starting shortly after the decision. Commercial operation was slated for 2025. But the FID remains on hold and permits are pending. The company has missed two construction start deadlines so far, despite the state of Louisiana’s promises of tax dollars and a supportive permitting environment.

This report reviews the financial risks facing the project. Those risks are discrete in nature, but cumulatively they should tell Mitsubishi that the proposed methyl methacrylate plant is the wrong project, at the wrong place and time, with the wrong financial scenario.

A summary of those risks makes the case.

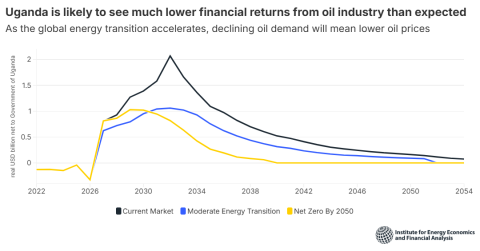

- The economy is growing at a much slower rate than when the Geismar plant was planned in 2014. A host of factors driven by war and the fear of war—as well as a realignment of markets reflecting globalization and national security tensions—will slow the economy and with it, the growth prospects of many petrochemical commodities, including MMA. Slow growth in the current paradigm impairs profits.

- The MMA market is oversupplied both in the United States and globally. The net result of new capacity additions is likely to lower the utilization rate of U.S. MMA producers—an impact that reflects oversupply and with it, flat pricing and tighter margins. Existing markets will not welcome the new MMA capacity.

- New plant prospects have weakened. Low-cost natural gas cost spurred a new build trend but the cumulative risk picture of higher cost construction and diminishing off-taker markets has undermined this strength. Several U.S. petrochemical projects have been canceled, delayed, or have confronted regulatory hurdles highlighting the market weakness of large petrochemical investments. Consistent public concerns over environmental and climate issues are gaining credibility with institutional concerns voiced by credit agencies and shareholders posing additional risks.

- Sustainability plans are altering capital investment in traditional MMA production. The Geismar facility relies on fossil fuels. Investments in alternative MMA facilities that no longer rely on fossil fuel feedstocks, as well as the adoption of new PMMA recycling technologies, may absorb market share that traditionally has been the domain of new virgin MMA facilities such as the proposed Geismar project. Ironically, Mitsubishi is a leader in the next wave of fossil-free technologies.

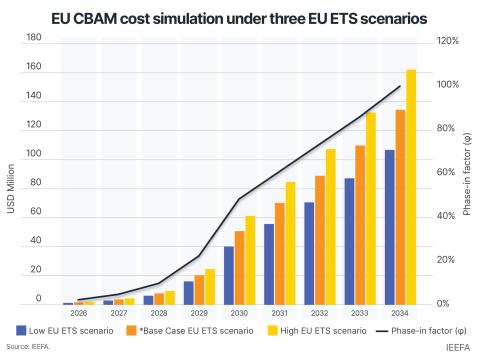

- Geopolitical factors are constraining U.S. exports. Traditional trade routes to Asia and the Middle East are increasingly uncertain, and a host of regulatory and policy factors in Europe are likely to curtail future exports from the United States.

- Mitsubishi’s stakeholder outreach fails to meet the test of corporate sustainability and human rights standards.

The strength of the energy transition is a confounding factor for Mitsubishi. The company, like most of the producers of MMA, is moving away from a production process that relies on cyanide, a poisonous substance. The preferred alternative today for MMA production is an ethylene-based production model. The improvement is meant to protect the public and Mitsubishi workers from cyanide. The downside is that ethane (natural gas) is used to produce ethylene, and the process emits significant amounts of greenhouse gas emissions—a step backward for climate change.

Confounding the picture, Mitsubishi and its primary competitor, Röhm, have independently produced a “biofuel” MMA that does not rely on fossil fuels. Experimental success has now led Mitsubishi to commence construction on a biofuel plant in India. With the MMA market oversupplied and economy slowing, there is little need for new capacity, especially using traditional, soon-to-be obsolete technology and production processes. The company has time to improve on the operational performance of its new biofuel plant before the market needs new capacity. These sustainability considerations combine with the risky nature of the project’s standalone profitability. During an inflationary period, the cost of the plant has risen, while MMA commodity prices are looking to be relatively flat for the next several years. MMA profits have been sagging for the company and are likely to continue to do so through 2024 and into 2025.

Community sentiment is decidedly in opposition to this plant, a factor that is noted by credit agencies as part of the evolving global outlook for petrochemical facilities. The fact that the proposed plant is sited in Louisiana’s Cancer Alley—an area along the Mississippi River between New Orleans and Baton Rouge that is largely populated by African-Americans and has a disproportionately heavy concentration of polluting industrial facilities—means Mitsubishi will be entangled in a decades-long dispute involving issues of racial inequality and environmental justice. Even if Louisiana’s state government approves environmental permits, the project still faces market and political forces that place it at risk.

Mitsubishi’s decision to delay the project demonstrates its uncertain status. The two years of “wait-and-see” have brought greater risk in the form of rising construction costs and commodity price stagnation. The choices Mitsubishi makes in this matter will reveal whether the company is committed to an ambitious sustainability plan. The choice will determine whether Mitsubishi will cut emissions or increase them. And the overall decision will reflect the company’s commitment at the highest levels to sustainability, human rights and its investors.