Industrial energy efficiency to curb Bangladesh's short-term LNG demand growth

Download Full Report

View Press Release

Key Findings

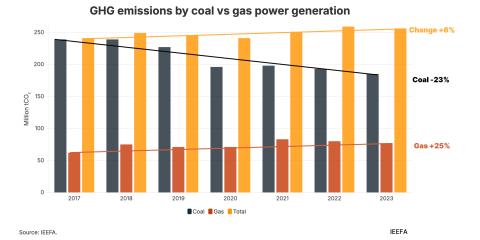

Bangladesh’s plan to power its economic development with LNG imports was not designed to cope with extreme global fuel market volatility, depreciation of the local currency and weak fiscal conditions.

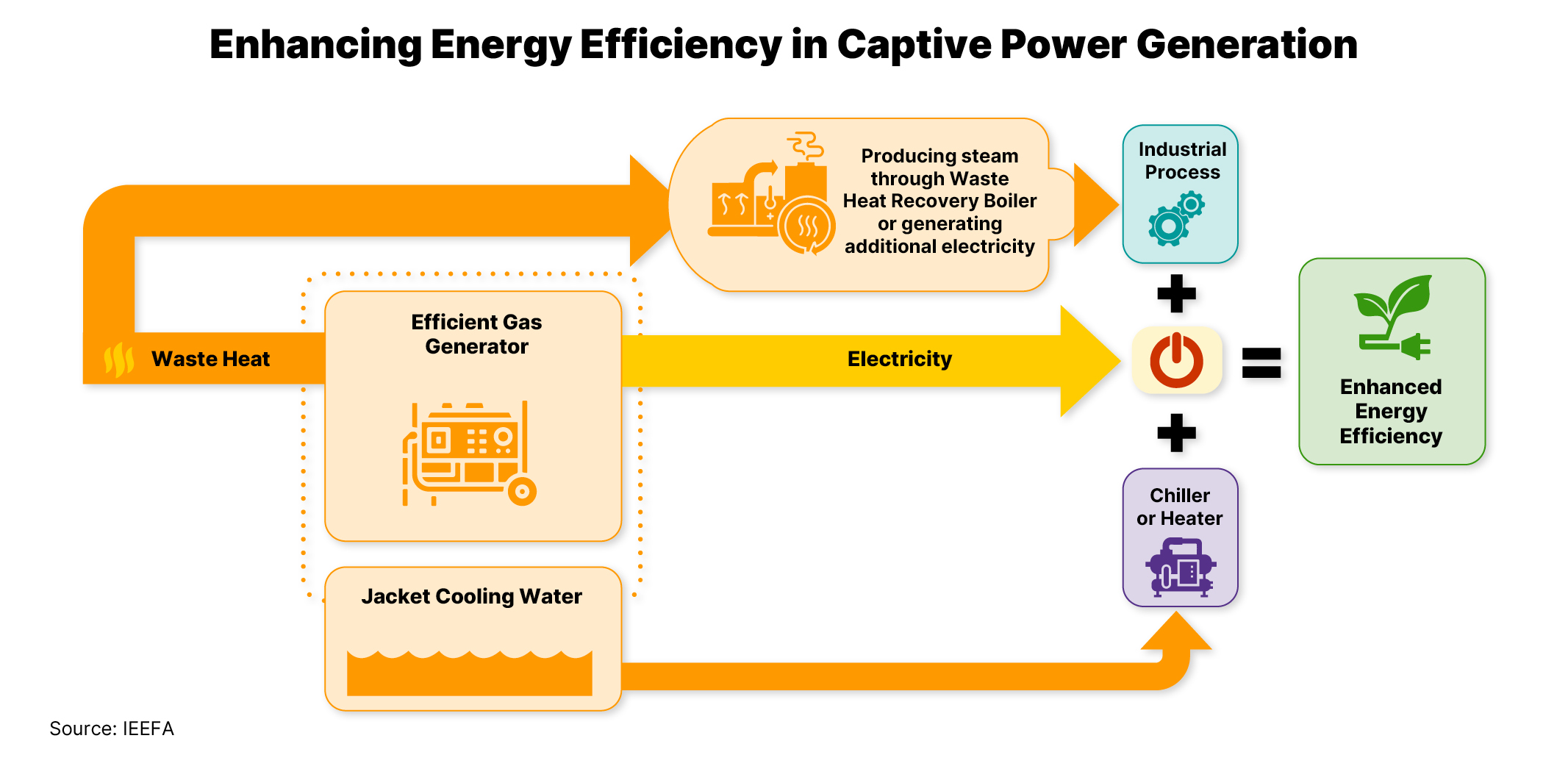

Greater efficiency in gas-fired captive power generation and productive use of waste heat can reduce LNG imports by 50.18Bcf and save Bangladesh US$460 million a year.

This study finds that the average efficiency of industrial gas-fired captive generators is 35.38%, which can be improved to 45.2% with high-efficiency generators.

The high dependence on gas is raising import bills and with it, the tariffs paid by consumers. Bangladesh must urgently re-evaluate its energy strategy, and take steps to improve energy efficiency to contain the growing demand for gas.

Even as global fuel prices stabilise, Bangladesh struggles to import sufficient liquefied natural gas (LNG) to satisfy escalating demand. So rather than import more LNG, the country can save almost half a billion dollars a year by reducing demand for this highly volatile fossil fuel. The solutions do not lie offshore but closer to home, such as in replacing the nation’s vast stock of ageing, inefficient captive gas-fired power generators. Replacing these with efficient models, which are readily available, may incur an upfront cost, but this study shows that the capital outlay for this is recouped between 1.5 and five years. The return on investment in waste heat recovery is only about one year. Weaning Bangladesh off its LNG imports will take time but decision-makers must plan and act now, lest the country is left exposed to the next global shockwave.

Cheap and subsidised natural gas has been the centrepiece of Bangladesh’s energy system since the early ’70s. Used extensively in power generation, industrial processes and other applications, gas has powered the country’s economic progress.

However, the insatiable demand for gas outpaced local production, directly affecting the country’s energy supply system. With limited success in renewable energy, spiralling gas demand in different sectors and concerns about long-term energy security, the government frontloaded efforts to import liquefied natural gas (LNG) to supplement local gas production.

Bangladesh entered the LNG market in 2018 with a modest import of 31.45 billion cubic feet (Bcf) of LNG. In 2023, imports swelled to 238.72Bcf, more than seven times the 2018 figure. Over the six years since 2018, rapidly rising imports in a volatile global market exposed Bangladesh’s energy sector’s weak financial health earlier than anticipated. This is a clarion call to listen and respond accordingly.

As we stand today, there is a need for policy-level intervention to assess the benefits of improving energy efficiency to contain increasing LNG demand in the short- to medium-term instead of only enhancing regasification capacity and increasing imports. There is also concern about the inefficient use of gas, for example, in captive power generation, which provides uninterrupted electricity supply to industries amid the lack of reliable grid electricity.

Bangladesh is unlikely to abandon LNG imports in the foreseeable future. However, to curb increasing demand, it will need to draw on all available avenues, such as enhancing energy efficiency in captive power generation.

This report builds on available evidence and a survey conducted by IEEFA of 51 industries with 124 gas-fired captive generators with a combined generation capacity of about 250 megawatts (MW). We find that the average efficiency of these generators is 35.38%, having improved from 30% identified in a previous assessment a decade earlier. However, as 45.2% efficient generators are available in the market, there is scope for further improvement and an associated gas consumption reduction.

Moreover, this study finds that 54.28% of the sample generators have an operational age of more than eight years. Although age is not the only parameter affecting generator efficiency, when industries procured the old stock of generators, the rated efficiency was not as high as today. For this study, we ran a regression model to check the association between the age of generators and efficiency and found a strong correlation.

The payback of replacing inefficient generators is also quick.

This study further finds that 44.22% of industry samples do not use waste heat released by generators, while 79.6% do not use jacket cooling water in productive applications. By using the waste heat recovery boiler/plant and jacket cooling water in a chiller or heater, a substantial amount of gas can be saved. The return on investment for both interventions is lucrative.

This study, therefore, recommends replacing old and inefficient generators with 45.2% efficient generators and utilising both waste heat available in the exhaust gas and jacket cooling water to significantly enhance efficiency in captive generation.

Enhancing Energy Efficiency in Captive Power Generation

The proposed energy efficiency measures can help Bangladesh reduce LNG imports by 21% and save US$460 million a year.

Energy efficiency improvement in captive generation is highly expedient as the capacity of gas-fired captive generators exceeds 3,000MW. In some scenarios of the Integrated Energy and Power Master Plan (IEPMP), gas-fired captive generation will have an important role in the country’s energy system right through to 2050.

The technical energy efficiency potential in captive power generation is attractive. Yet, the lack of credit facilities has often hampered the uptake of energy efficiency measures, despite the convincing financial returns. Low-cost financing vehicles available in Bangladesh can derisk investment in energy efficiency and mobilise private capital, but the pool of funds is limited.

Bangladesh Bank may consider establishing a dedicated low-cost revolving funding facility for industrial energy efficiency with support from multilateral development banks (MDBs), similar to the previous Financing Brick Kiln Efficiency Improvement Project. With the rising demand for finance, Bangladesh may also look into bonds to raise funds, particularly for large energy consuming industries looking to reduce energy consumption and minimise their environmental footprint.

With regulations for manufacturing environment-friendly products tightening around the world, any complacency in undertaking energy-saving measures will likely erode the competitiveness of industries. As the era of cheap energy comes to an end, and the government makes pricing more competitive in the foreseeable future, enhancing energy efficiency will be financially more rewarding.

While the path to limiting energy price spikes and import dependence has narrowed, it is still possible – if Bangladesh harnesses its strong energy efficiency potential and deploys renewable energy with greater ambition. Without decisive action, the window of opportunity may close sooner if all planned infrastructure for imported fossil fuels is built, and the country is locked into even greater dependence on imports, at the mercy of volatile global markets.

Bangladesh can accelerate the promotion of energy efficiency by building on policy foundations that are already in place. For instance, energy efficiency and conservation rules require mandatory energy auditing of designated consumers, including industries. The Sustainable and Renewable Energy Development Authority (SREDA), established to accelerate the deployment of clean energy, may design measures to swiftly scale up energy efficiency, both in captive power generation and industrial processes. Likewise, it may stimulate renewable energy deployment in the country by surmounting barriers. The government would also need to expedite investment in modernising the grid to attract industrial consumers to shift to grid electricity gradually. Such a comprehensive approach will reduce the country’s dependence on gas far more than efficiency improvements in captive generation alone.

The country’s highly import-dependent energy sector is prone to challenges, but a sense of urgency and firm commitment by policymakers can drive it towards a more secure and sustainable future.