IEEFA: Boosting domestic solar PV manufacturing will fuel green hydrogen takeoff in India

As a late-starter in solar module manufacturing and electric vehicles, India missed a golden opportunity to drive the cost advantages of economies of scale. However, with the deployment of green hydrogen India is ensuring the building blocks are in place for a hydrogen economy that will not only meet domestic needs but also provide export opportunities.

On 17 February, the Ministry of Power unveiled India’s much-awaited first green hydrogen policy

On 17 February, the Ministry of Power unveiled India’s much-awaited first green hydrogen policy. The guidelines are a step in the right direction to ensure that green hydrogen is used to decarbonise and reduce emissions in the hard-to-abate sectors like fertiliser manufacturing, oil refining and others. This will also enable the government to meet its other objectives of energy security, energy self-reliance, reducing imports of expensive fossil fuels and thereby the import bill. It is also a huge opportunity to build a new billion-dollar industry that will create jobs.

The green hydrogen policy allows for a single-window clearance system, the allotment of land in renewable energy parks, priority access to the inter-state transmission network, open access procurement within 15 days, waiver of inter-state transmission charges, a 30-day energy banking policy and other measures. Through these measures, the government is promoting the transmission of renewable energy and the setting up of green hydrogen production near to where it will be consumed. This also includes bunkers near ports for storage and easy export of green ammonia.

Distribution companies (Discoms) are incentivised by the inclusion of the sale of renewable energy to manufacturers of green hydrogen/green ammonia as part of their renewable purchase obligation (RPO). Also, any consuming entity is entitled to claim RPO compliance, and any energy consumed beyond the obligation of the producer will be considered part of the local Discoms’ RPO compliance.

It’s critical that renewable energy and electrolyser costs go down in the next few years

Help to meet RPO obligations, in addition to being able to charge for the cost of energy, wheeling charges and a small margin, will encourage Discoms to act as enablers of green hydrogen, promoting the setting up of manufacturing facilities in their areas – a win-win situation for Discoms and manufacturers. However, states should also provide a conducive environment by waiving the cross subsidy charge or keeping it low to improve the commercial viability of green hydrogen.

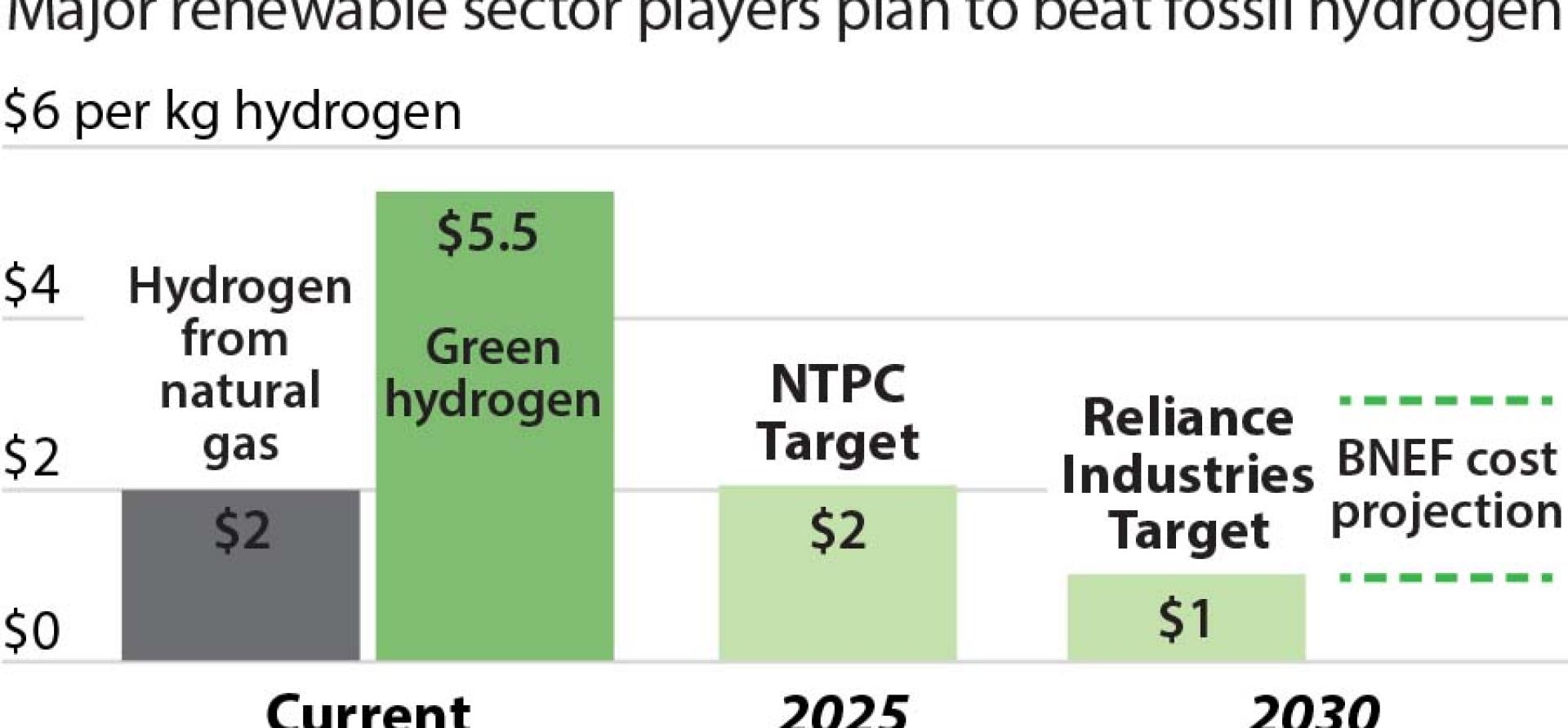

While the policy tackles some supply-side aspects, the demand for green hydrogen is largely dependent on its cost. Currently, green hydrogen is US$5.5 per kg compared to below US$2 per kg for hydrogen produced with natural gas.

For adoption at large scale it is critical that renewable energy and electrolyser costs – the major components driving the cost of green hydrogen – go down in the next few years. BloombergNEF predicts the levelised cost of energy (LCOE) of solar PV will fall from US$60/MWh currently to US$30/MWh by 2030 and US$20/MWh by 2050. The cost of green hydrogen is predicted to fall to US$0.9-3 per kg by 2030 and US$0.7-1.8 per kg by 2050.

Domestically produced, cheaper electrolysers combined with ultra-low cost renewables backed by clear policy support will help realise India’s green hydrogen potential.

The government needs to accelerate deployment of renewable energy. However, the imposition of various tariff and non-tariff barriers, such as the basic customs duty on solar equipment and the Approved List of Models and Manufacturers, are creating headwinds for the renewable energy sector and will drive prices upwards. To build the domestic solar manufacturing base, the government needs to give a fillip through Production Linked Incentive (PLI) schemes, while avoiding tariff and non-tariff barriers until manufacturing has reached a scale that can support 30-35GW of annual installation of renewable energy.

In order to improve the commercial viability of green hydrogen, prices of renewable energy will have to be equal to or below Rs2/kWh. Players like NTPC, Indian Oil Corporation, Reliance, Adani and JSW have big plans to create a green hydrogen economy in India. NTPC is eyeing a US$2 per kg benchmark cost by FY2025/26 for green hydrogen production. Reliance has set a target of US$1 per kg by 2030 by investing US$75 billion in renewable infrastructure including generation plants, solar panels and electrolysers. Reliance has in fact partnered with renewables pioneer Henrik Stiesdal to develop and manufacture hydrogen electrolysers.

The government now needs to provide long-term certainty

The government should further support these positive developments by implementing a green hydrogen consumption obligation (GHCO) mechanism for fertiliser production and petroleum refining, similar to the RPO. This would provide strong offtake visibility for the developers and incentivise investment into production facilities.

Both the public and private sector are upbeat, and the green hydrogen policy provides them with the right incentives to scale green hydrogen. The government now needs to provide long-term certainty by not withdrawing these benefits in the next few years. Policy certainty will be key for developer and investor confidence.

By Vibhuti Garg, Energy Economist and Lead India and Kashish Shah, Energy Finance Analyst at the Institute for Energy Economics and Financial Analysis (IEEFA)

This commentary first appeared in Financial Express.

Related articles:

IEEFA/JMK: Government incentives brighten outlook for Indian solar manufacturing

IEEFA: India’s technology path key to global steel decarbonisation

IEEFA Update: Financing the future of green hydrogen

IEEFA India: There has never been a better time for domestic solar module manufacturing

IEEFA India: Renewable energy capacity additions poised to reach five-year high