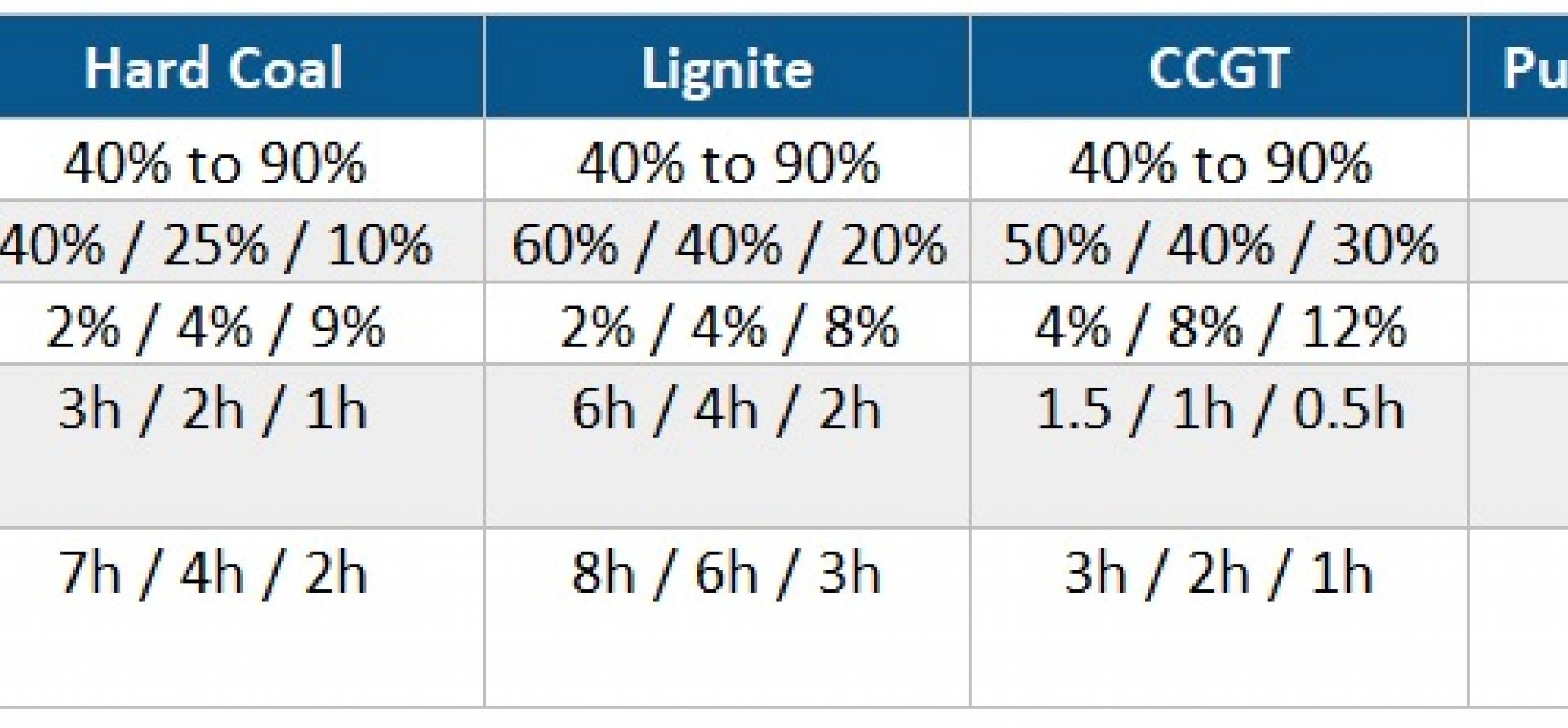

Source: GIZ, IEEFA, Fluence.

Note: CCGT is combined cycle gas turbine (gas-fired generation). Minimum load is the least possible load a plant can operate at relative to its rated capacity. Ramp rate is how fast a plant can change net power during operation. Start up time is to minimum load.

Gas-fired power plants (CCGT) in general rate better on flexibility parameters with quicker ramp up and ramp down rates and minimum generation levels.

As shown in the table, the CCGT plants have greater ramp rates and shorter start up times but for higher minimum loads. CCGT plants can ramp up net generation at 12% per minute compared to coal and lignite, 9% and 8% for respectively. CCGT plants can operate at a minimum load of 30% (coal and lignite, 10% and 20%).

In recent years, economic constraints – primarily the lack of a domestic gas supply – have limited the 25GW of gas-fired capacity to extremely low utilisation, below 20%.

In terms of flexibility, battery storage is the most proven technology to provide fast ramp-up and ramp-down energy dispatch and fast frequency service. Batteries ramp-up to full load in a minute and can also absorb excess power from the grid.

Battery market charging up

In our view, recent market and regulatory developments indicate India’s battery storage market could boom in no time. Continuing a decade-long deflation in costs, solar plus batteries are cost competitive with new coal-fired plants in markets such as the U.S. and Australia, where battery storage development is burgeoning.

In India, there is a similar prospect for a surge in uptake of battery storage as the learning-by-doing experience deepens as new projects, backed by tenders from government-owned entities such as NTPC and Solar Energy Corporation of India (SECI), are executed.

Solar plus batteries benefit from a decade-long deflation in costs

ReNew Power, one of the biggest renewable energy developers in India, and Fluence Energy, a leading battery technology provider, have announced a joint venture to develop a 150MWh storage facility in Karnataka. ReNew Power has won numerous RE plus storage tenders and the battery project will play a key role in delivering firmed RE capacity.

The cost of batteries could reduce further with local manufacture. The government is striving to support the localisation of batteries’ value-chain with a Production-Linked Incentive (PLI) scheme worth ₹18,100 crore ($2.47 billion) for 50GWh of battery storage for electric vehicles (EVs) and stationary battery storage. The tender has been oversubscribed 2.6 times with bids received for 130GWh of battery manufacturing capacity.

The interested parties are Reliance New Energy Solar, Hyundai Global Motors, Ola Electric Mobility, Lucas-TVS, Mahindra & Mahindra, Amara Raja Batteries, Exide Industries, Rajesh Exports, Larsen & Toubro, and India Power Corporation.

Optimal use of power assets

CEA estimates 27GW/108GWh of battery storage capacity will be required to integrate 450GW of VRE by March 2030. Optimised power assets, both energy and grid services, is key for transitioning to a modern and cost-effective power economy.

Coal and gas-fired power with favourable cost economics could be retrofitted to operate flexibly, enabling a diversified pool of assets to compete to provide energy and grid ancillary services.

A recent report from Wartsila recommends regionally co-optimising energy and ancillary services, simultaneously creating two different value (revenue) streams, bringing down system level cost and potentially driving investment into the assets that could provide flexibility.

This article was first published in The Hindu Business Line.

Related articles:

IEEFA India: What’s in store for renewable energy this budget?

IEEFA India: Volatile LNG prices present opportunity to switch to cleaner fuel sources

IEEFA India: How round-the-clock renewables point to optimum use of energy generation and infrastructure