IEEFA update: Australia’s aluminium smelters need a technology retrofit to offer demand response capacity

Australia is facing an ongoing energy crisis in the face of a technology driven market disruption.

There is a growing need for significant new investment to replace the ageing thermal power fleet

In addition to ongoing and destabilising policy uncertainty, an ageing and increasingly unreliable coal-fired power station fleet is losing cost competitiveness as subsidised coal supply contracts expire and the market pivots from the now entirely outdated baseload concept towards the new need for flexible, on-demand peaking power capacity.

Further, the rapid uptake of cleaner, cheaper but intermittent wind and solar generation has yet to be fully buffered by energy storage, and investment in new peaking power capacity and interstate grid connectivity has not kept pace with end-of-life thermal power retirements.

AUSTRALIA’S FOUR REMAINING ALUMINIUM SMELTERS IN TASMANIA, QUEENSLAND, NEW SOUTH WALES AND VICTORIA ARE FACING IMMENSE STRATEGIC CHALLENGES operating in this environment.

The rising cost of domestic coal and gas has resulted in a doubling of electricity prices this decade, and policy uncertainty has undermined investor confidence, reducing investment in new low cost generation capacity.

Rising coal and gas costs (causing higher electricity prices)

In addition to a recent global slump in aluminium prices following a downward slide since 2011, there is a growing need for significant new investment to replace the ageing thermal power fleet.

In the face of high energy prices and lack of progress on decarbonisation, the Australian aluminium smelter sector is now strategically challenged, even as the AUD/USD hits decade lows and renewable energy is getting ever cheaper.

Last year, owner of three of the Australian smelters, chief executive Jean-Sebastien Jacques from Rio Tinto said he was in discussion with utilities and the federal government to find a way to lower electricity prices, saying “Australia should have a cheap, reliable, globally competitive source of energy and today it is not the case and it is an issue for us.”

OVER THE LAST DECADE, THE MAKE-UP OF ELECTRICITY GENERATION IN AUSTRALIA’S NATIONAL ELECTRICITY MARKET (NEM) HAS CHANGED RAPIDLY.

Aluminium smelting in Australia is at a crossroads

Rising coal and gas costs (causing higher electricity prices) combined with the financial markets’ projection of some level of carbon pricing (in the medium term) has meant that investment in new coal-fired generation capacity is now a high cost option lacking in bankability.

While current generation is still dominated by traditional sources of energy (coal, hydro-electric and gas), there has been a rapid expansion in market share from least-cost variable renewable energy (VRE) sources – namely solar and wind energy.

The higher uptake of VRE sources in the NEM is impacting energy reliability and security, absent sufficient buffering by batteries, pumped hydro storage (PHS) and other dispatchable generators, and this lack of reinvestment is driving up the cost of energy (especially peak spot pricing) to large-scale industrial users, including smelters.

The Australian Energy Market Operator’s (AEMO) Integrated System Plan (ISP) – the roadmap for electricity generation – shows the NEM will be increasingly susceptible to unexpected shocks (reduced energy output from wind/solar, extreme weather, failure in grid interconnectors) with resulting variability in spot pricing, given the absence of a sensible energy policy which has impeded the grid modernisation.

Thermal power generation will continue to lose market share to VRE

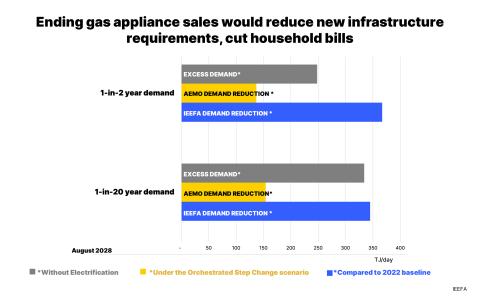

The AEMO has the authority to temporarily curtail power to smelters when energy generation is insufficient to meet demand. Without new demand-side response (DSR) capacity and large-scale energy storage technologies in the grid, forced curtailments are more likely to occur with increasing proportions of VRE generation (and retiring baseload) in the energy mix.

In short, aluminium smelting in Australia is at a crossroads.

Continuation of the current trajectory will inevitably mean an increasingly difficult battle for existence in an increasingly carbon constrained world. Or, smelters could modernise and become flexible in energy consumption, dramatically reducing overall electricity costs to both the smelter and the power system overall.

TO IEEFA IT IS CRITICAL THAT AUSTRALIA’S SMELTERS SEIZE THIS TECHNOLOGY OPPORTUNITY and reorientate their businesses towards more flexible electricity consumption.

VRE is now providing the least cost solution to the rising need to both replace end of life thermal capacity and decarbonise the Australian economy.

In AEMO’s Integrated System Plan (ISP), thermal power generation will continue to lose market share to VRE. AEMO concludes that the NEM needs a significant increase in flexible on-demand thermal power capacity, battery and PHS, increased interstate grid connectivity, and management of demand side response (DSR). DSR provides the means to vary consumers’ electricity demand to achieve balance in the power system with both variable supply matched by increasingly variable demand.

The potential for smelters to provide an indefinite duration of DSR is of irreplaceable value

DSR allows a smelter to release energy back into the grid when most needed to meet the net energy shortfall. It would also increase the grid’s capacity to benefit by increasing the share of lower cost VRE, reducing the emissions intensity of the system by flattening the overall demand profile.

With the Australian Energy Market Commission (AEMC) giving the go-ahead for private players – in addition to retailers – to provide wholesale DRS, aluminium smelters in Australia are ideally positioned to be paid to provide valuable DSR services. This would not only reduce electricity costs to the smelter, but also reduce the overall operational costs of the power system.

Furthermore, the potential for smelters to provide an indefinite duration of DSR is of irreplaceable value when faced with seasonal electricity supply shortages and increasingly extreme weather events.

This will enable the smelters to manage and even benefit from price variation whilst driving a progressive grid decarbonisation, dramatically improving the viability of the business model.

Tim Buckley, Director of Energy Finance Studies, IEEFA Asia Pacific

This is an excerpt from The Australian Energy Crisis, Its Impact on Domestic Aluminium Smelting and Potential Solutions, authored by IEEFA’s Tim Buckley, with David S. Wong, Geoff Matthews, Alton T. Tabereaux, and Mark M. Dorreen, published February 2020.

Related articles:

Energy transition presents high risks and big opportunities for Australia

Gas reservation policy would reduce electricity prices in Australia

How ‘Gold-Plating’ the Australian Electricity Grid Is Killing Off Coal-Fired Generation